| Address: | PDS Enterprise Inc. 1650 West Artesia Blvd, Suite 278 Gardena, CA90248 |

| Phone: | 1-843-408-0142 |

| Email: | pdsenterprise@gmail.com sales@coolprototyping.com |

Home>Popular Page

25. Mechanical Prototyping Processes

Our product design team works with clients who have varied schedules and budgets. To best serve their special individual needs, we use a variety of rapid prototyping methods to create mechanical models for test. Sometimes the parts are used for engineering purposes, and other times the parts are purely cosmetic for interdisciplinary design reviews. Understanding the pluses and minuses of each process allows us to minimize time and budget while achieving the design objectives. Below is a short summary of the processes we use most often for small quantities of mechanical parts.

Stereolithography (SLA)

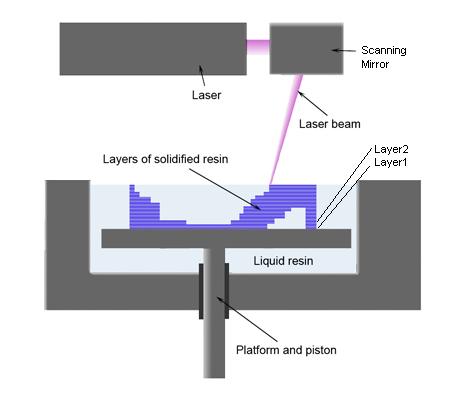

How it works: SLA is an additive prototyping process in which parts are built layer by layer from the ground up. The process begins by raising a platform up to the top of a pool of UV curable photopolymer resin. A squeegee wipes a thin layer of photopolymer across the top of the platform (about 0.004" thick). A UV laser is activated which bounces off a movable mirror, and strikes the photopolymer hardening it at the point of contact. A computer connected to the machine moves the mirror in an x-y pattern so the laser can trace out the rest of the first layer. Once the first layer is complete, the platform drops down one layer thickness (.004") and the process begins again. Once all the layers are complete, the part is removed from the machine for cleaning and one final cure under a UV light source.

SLS

How it works: SLS is similar to SLA, but uses powder instead of photopolymer resin. In SLS, a laser cures small granules of nylon powder into any shape. The powder is available in a variety of blends, some of which are fuel resistant, heat resistant, or reinforced with glass for stiffness. The process is very fast, so big parts can be produced in one to two days. Additionally, the parts are ready to use right out of the machine which saves time as well. Another attractive feature of this process is the ability to sinter multiple parts of an assembly all together at once in its assembled state.

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly.

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly. Marsha Dunmyre

CA, U.S.A

Cool Prototyping Copyright 2008-2009 © All Rights Reserved. Rapid Prototyping