Product Design

Product Design

Rapid Prototyping

Rapid Prototyping

CNC Prototyping

CNC Prototyping Rapid Prototyping

Rapid Prototyping Stereolithography Apparatus (SLA)

Stereolithography Apparatus (SLA) Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing (LOM)

Custom Molds - Plastic Molds

Custom Molds - Plastic Molds

Plastic Molding

Plastic Molding

Production Tooling

Production Tooling

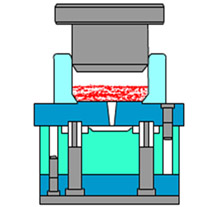

Plastic Molding – Compression Molding

Compression molding has been employed for manufacturing plastic parts since the advent of the plastics industry. This method was utilized the by bakery industry for cookie and cake molding before plastic materials existed.

Compression molding has been employed for manufacturing plastic parts since the advent of the plastics industry. This method was utilized the by bakery industry for cookie and cake molding before plastic materials existed.

Compression molding is most commonly used to manufacture thermoset plastic parts, and it is suitable for thermoplastics also. The raw material for compression molding is usually in the form of granules, putty-like masses, or preforms. The material is placed into an open, heated mold cavity. The mold is closed and pressure is applied to force the material to fill the cavity, thereby conforming to its shape. Often a hydraulic ram is utilized to produce sufficient force during this process. The heat and pressure are maintained until the plastic material is cured.

Common plastic materials used in compression molding processes include:

- Polyester

- Polyimide (PI)

- Polyamide-imide (PAI)

- Polyamide-imide (PAI)

- Polyetheretherketone (PEEK)

- Fiber-reinforced plastics

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly.

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly. Marsha Dunmyre

CA, U.S.A

Cool Prototyping Copyright 2008-2009 © All Rights Reserved. Rapid Prototyping