Product Design

Product Design

Rapid Prototyping

Rapid Prototyping

CNC Prototyping

CNC Prototyping Rapid Prototyping

Rapid Prototyping Stereolithography Apparatus (SLA)

Stereolithography Apparatus (SLA) Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing (LOM)

Custom Molds - Plastic Molds

Custom Molds - Plastic Molds

Plastic Molding

Plastic Molding

Production Tooling

Production Tooling

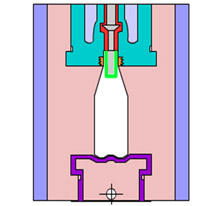

Plastic Molding – Blow Molding

Blow molding is a manufacturing process used to create hollow, thin-walled plastic objects such as bottles and containers, cases and bellows.

Blow molding is a manufacturing process used to create hollow, thin-walled plastic objects such as bottles and containers, cases and bellows.

A typical blow molding process begins with a heated hollow thermoplastic tube, also known as preform or parison. The plastic tube has a hole in one end, allowing compressed air to enter. The plastic is inflated into the closed chamber of a divided mold to conform to the shape of the mold’s cavity. The molded plastic is left to cool and harden. Once released from the mold, the plastic part can be processed to have the holes rimmed or residues trimmed.

Some plastics are not suitable for blow molding. The most frequently used materials are:

- Low Density Polyethylene (LDPE), High Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PET)

Interested or any question, please contact us.

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly.

We are constantly looking for new products in order to grow our business and Invention Home has enabled us to streamline that process much more quickly. Marsha Dunmyre

CA, U.S.A

BROWSE MORE

Cool Prototyping provides "one-stop" product design service: rapid prototyping, plastic molds, custom molds, production tooling and plastic molding.

Cool Prototyping Copyright 2008-2009 © All Rights Reserved. Rapid Prototyping

Cool Prototyping Copyright 2008-2009 © All Rights Reserved. Rapid Prototyping